We deliver to you every day from 7:00 to 23:00

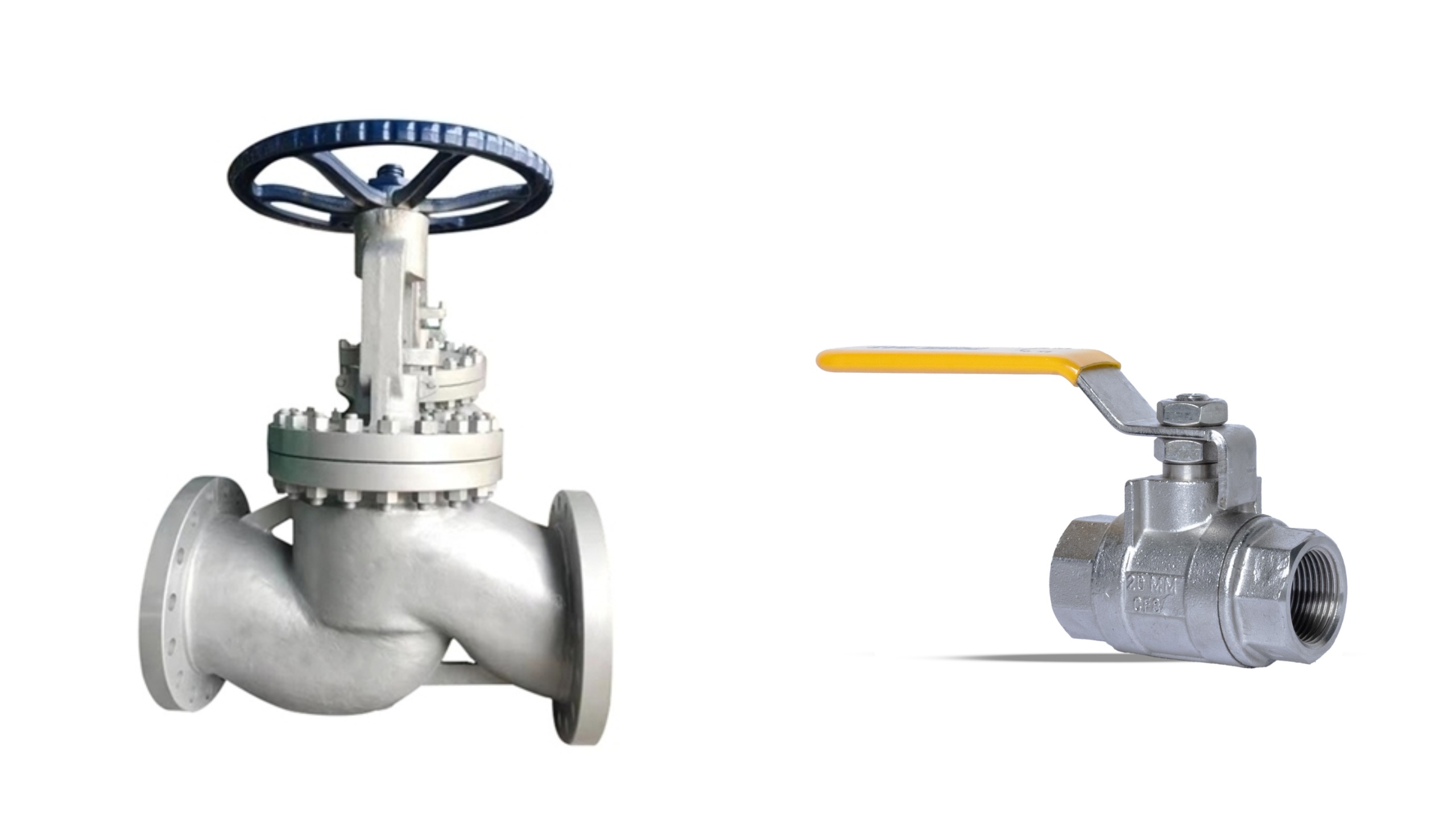

Globe Valve vs Ball Valve for Flow Control Applications: A Complete Comparison

Backflow problems, pressure instability, and irregular flow control often lead to system inefficiencies and costly downtime. Industries handling steam, chemicals, or corrosive fluids frequently evaluate valve types based on performance, safety, and flow behavior. In this blog, we will be discussing Globe Valve vs Ball Valve, a detailed comparison often searched by engineers working with a Globe Valve vs Ball Valve manufacturer in Europe. These two valves are commonly compared because they help address challenges such as valve orientation, backflow issues, pressure drop, and valve inspection planning.

Selecting the right valve for flow control is never a one-size-fits-all decision. Globe Valves and Ball Valves are two of the most widely used options, each offering unique strengths for industrial pipelines. While both handle fluid movement, their internal structure, flow characteristics, and suitability for corrosive applications differ significantly. Because of these differences, engineers often evaluate them side-by-side before finalizing a specification.

This blog highlights why these two valves are frequently compared and how they perform in flow-sensitive and corrosion-prone environments.

Globe Valve vs Ball Valve

Why These Valves Are Often Compared

Globe and Ball Valves share similar application spaces but operate very differently. Engineers compare them because:

- Both help mitigate backflow and maintain stable fluid direction.

- Both follow rigorous valve inspection and performance standards.

- Both can be manufactured in corrosion-resistant materials such as CF8M, SS316, F51, Alloy 20, and more.

- Both operate in oil & gas, chemical processing, water-treatment, marine, and power-generation sectors.

Their contrasting design philosophies make them suitable for different functional requirements within the same facility.

Design & Operation Differences

Globe Valves

A Globe Valve uses a rising stem with a plug that moves vertically to the seat. Its design supports accurate throttling and controlled pressure reduction. Because fluid must change direction inside the valve, it allows smoother modulation across varying conditions.

Ball Valves

A Ball Valve operates through a quarter-turn motion. When the ball’s bore aligns with the pipeline, the flow passes freely; when rotated, the flow stops instantly. This design provides quick shutoff, low flow resistance, and simplified operation compared to linear-motion valves.

Flow Characteristics

Globe Valves

- Designed for precise flow regulation, making them ideal for applications that require gradual change in flow rate.

- The internal flow path creates a higher pressure drop, which can be advantageous when pressure control is required.

- Commonly used in steam lines, condensate systems, chemical dosing, and applications needing predictable modulation.

Ball Valves

- Known for minimal pressure drop due to their straight-through flow path.

- Best suited for clean liquids, gases, and systems where rapid isolation is valuable.

- Only certain specialized designs can handle throttling; standard versions support open-close duty more effectively.

Material Benefits for Corrosive Applications

Material selection plays a crucial role in valve longevity, especially where corrosive chemicals, seawater, or acidic media are involved. Both Globe and Ball Valves are available in durable alloys that help resist pitting, crevice corrosion, and erosion.

Globe Valves in Corrosive Service

- Available with trim options-stellite, hardened surfaces, corrosion-resistant alloys-making them suitable for high-temperature and mildly erosive systems.

- Used in chemical dosing, boiler feed lines, and industrial processes where smooth throttling helps protect downstream equipment.

Ball Valves in Corrosive Service

- Can be customized with PTFE seats, reinforced polymer seals, or metal-seated construction for abrasive media.

- Highly effective for corrosive pipelines due to fewer internal flow disturbances and strong sealing capability.

- Alloy 20, Duplex, Super Duplex, and SS316 options allow these valves to maintain performance even in aggressive chemical environments.

When to Choose Which Valve

Choose a Globe Valve When:

- You require consistent modulation or a precise flow adjustment.

- Pressure drop is acceptable or beneficial for system control.

- Applications include steam control, condensate handling, cooling water regulation, or chemical dosing.

- The system design demands stable throttling with predictable response.

Choose a Ball Valve When:

- You need rapid open-close action with minimal effort.

- A low-pressure drop is important for overall system efficiency.

- Pipelines handle corrosive or slurry-based fluids.

- The valve serves as an isolation point with occasional throttling (if specified for control duty).

Which Valve Is Ideal at What Time?

- For accurate flow control, Globe Valves are the preferred choice due to their linear-motion regulation.

- For fast isolation and low flow resistance, Ball Valves outperform due to their quarter-turn operation.

- For corrosive environments, both valves work well-material compatibility matters more than valve type.

- For preventing backflow and maintaining safe operating conditions, either valve can perform effectively when properly sized and installed.

Differentiation Table: Globe Valve vs Ball Valve

| Feature | Globe Valve | Ball Valve |

| Design Purpose | Designed for precise modulation and controlled flow reduction. Excellent for gradual adjustments. | Built for rapid isolation and straightforward operation. Ideal for quick shutoff needs. |

| Flow Path | Induces direction change, creating higher pressure drop but boosting flow control accuracy. | Straight-through flow that provides minimal resistance and low-pressure loss. |

| Operation | Linear stem motion provides fine-tuned control across various flow ranges. | Quarter-turn rotary motion offers fast response with simple mechanical design. |

| Corrosion Resistance | Available with hardened trims and corrosion-resistant alloys suited for high-temp and chemical applications. | Seats, seals, and ball materials can be customized for aggressive media and abrasive particles. |

| Primary Applications | Steam regulation, chemical metering, condensate control, and utility process lines. | Isolation in corrosive pipelines, gas service, water systems, and automated shutoff setups. |

Globe and Ball Valves both bring valuable strengths to flow control applications. Each design excels in different areas-one delivers stable modulation, while the other guarantees fast action and low resistance. Rather than choosing one “best,” it’s more effective to select the valve that aligns with your system’s medium, pressure, and flow behavior.

Whether your process involves chemicals, steam, seawater, or clean liquids, the right valve will help maintain performance and prevent costly operational issues. If you share your process conditions, media type, and pressure class, our engineers can help you select the most suitable Globe Valve or Ball Valve for your application giving you confidence in long-term flow stability and safety.

Recent Posts

- Pressure Seal Gate Valves: Design Principle and High-Pressure Service

- Valves Used in Chemical Processing Plants

- Single Offset vs Double Offset vs Triple Offset Butterfly Valves – What’s the Difference?

- Globe Valve vs Ball Valve for Flow Control Applications: A Complete Comparison

- Forged vs Cast Valves: Differences, Strength & Applications for Corrosive Environments