We deliver to you every day from 7:00 to 23:00

Floating vs Trunnion Ball Valves : Material Benefits for Corrosive Applications

Backflow problems, pressure drops, and corrosion damage are among the most common challenges in industrial piping systems. A small issue in valve performance can lead to system instability, product loss, or even downtime. Choosing the right ball valve plays a key role in keeping your process smooth, consistent, and dependable.

We will discuss Floating and Trunnion Ball Valves material benefits for Corrosive Applications, and understand how each valve design performs under different pressure and service conditions. We’ll talk about their construction, flow behavior, maintenance, and material choices that make them suitable for corrosive environments.

At Valves Only Europe, we craft valves that deliver steady performance across oil, gas, petrochemical, and marine industries. Our goal is to help you select the right valve design that keeps your system operating smoothly and securely for the long run.

Why Floating and Trunnion Ball Valves Are Often Compared

Floating and trunnion ball valves both control the flow of fluids through a spherical ball with a through-bore, but the way each is supported and sealed differs. They are often compared because:

- Both offer tight shut-off in corrosive environments.

- Each design suits a specific pressure range and torque requirement.

- Both can be built using corrosion-resistant materials like CF8M, F51 Duplex, or Super Duplex Stainless Steel.

These similarities often make selection challenging. However, understanding their engineering principles helps determine which is the better fit for your system’s pressure, flow, and media composition.

At Valves Only Manufacturer in Europe, our valves are designed to deliver smooth operation, minimal leakage, and long-lasting performance-even in demanding industrial conditions.

Design and Operation Differences

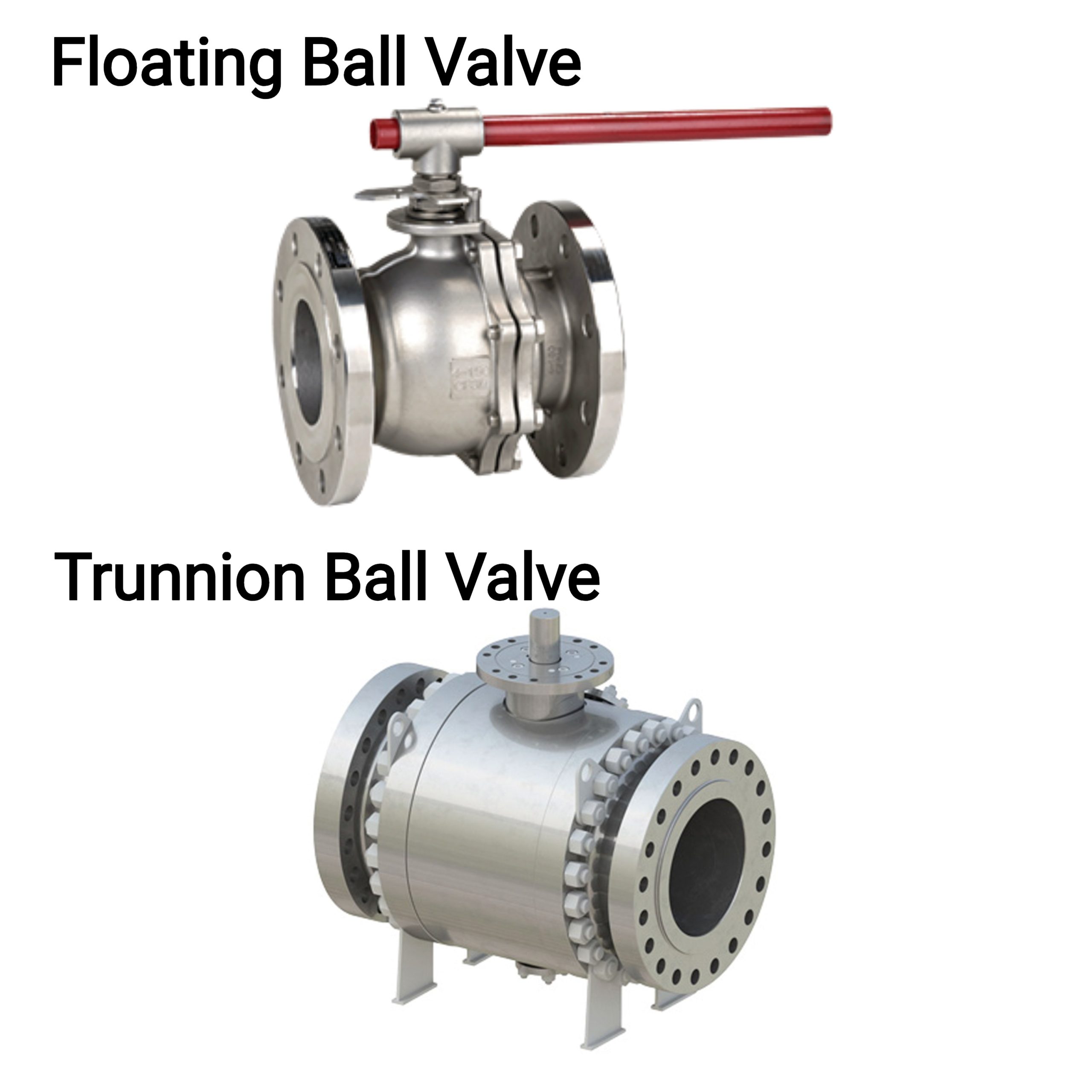

Floating Ball Valve

A floating ball valve has a ball held between two seats without a rigid mechanical anchor. When pressure builds, the ball moves slightly downstream to press against the seat, creating a tight seal.

- Ideal for low to medium pressure service.

- Commonly found in smaller bore sizes (DN15-DN200).

- Effective for clean, non-abrasive, or mildly corrosive fluids.

Its simple design makes it a practical choice for quick shut-off and straightforward maintenance.

Trunnion Ball Valve

In a trunnion ball valve, the ball is anchored at both the top and bottom using trunnion supports. Instead of the ball moving, the seats move towards it to achieve sealing.

- Best for high-pressure (Class 600-2500) and large-diameter pipelines.

- Handles corrosive, viscous, or abrasive fluids efficiently.

- Offers lower torque, reduced seat wear, and stable sealing.

This design provides extended service life and consistent flow even under changing pressure conditions.

Material Benefits for Corrosive Applications

In systems where valves face exposure to corrosive substances-such as saltwater, acids, or chemical mixtures-material choice determines how long the valve will perform and how well it maintains function.

- Duplex & Super Duplex Stainless Steel: Outstanding resistance to pitting, cracking, and chloride-induced corrosion. Excellent for offshore, desalination, and chemical process systems.

- CF8M (316 Stainless Steel): A balanced alloy offering strength and corrosion protection for most industrial and marine applications.

- Inconel & Hastelloy Alloys: Provide superior strength at high temperatures and resist aggressive chemicals, acids, and high-pressure gases.

- Carbon Steel with Overlay or Coating: Used in moderate conditions for economical, dependable performance.

- PTFE, RPTFE, and PEEK Seats: Deliver lasting sealing performance across temperature variations and resist chemical wear.

With these materials, our valves retain long-term strength, minimize corrosion impact, and maintain leak-tight operation even in severe environments.

Flow Characteristics and Performance

Both floating and trunnion ball valves offer full-bore designs, which minimize turbulence and pressure drop. However, their internal sealing dynamics affect how they perform under different loads:

- Floating Ball Valves deliver excellent shut-off at lower pressures but may experience seat wear at high differential pressures.

- Trunnion Ball Valves keep stable sealing under high pressure, reducing seat deformation and easing actuation.

Trunnion valves can also include double block and bleed functionality, offering extra system protection in critical applications.

Cost and Maintenance

Floating ball valves are affordable and lightweight, perfect for smaller pipelines and moderate-pressure systems. They’re easy to install and maintain thanks to their straightforward structure.

Trunnion ball valves, while more expensive initially, offer extended operational life. Their anchored ball design reduces wear and torque, minimizing servicing needs and downtime. For facilities running continuous operations, trunnion valves provide long-term dependability and steady flow performance.

| When to choose which valve | ||

| Factor | Floating Ball Valve | Trunnion Ball Valve |

| Operating Pressure | Works best for low to medium pressure (Class 150-600). | Suitable for high pressure up to Class 2500. |

| Valve Size Range | Compact, ideal for DN15-DN200. | Designed for DN200 and larger systems. |

| Seat Load & Wear | More wear due to ball movement. | Minimal wear, longer seat life. |

| Cost & Maintenance | Budget-friendly, easy to service. | Higher cost but minimal upkeep. |

| Application | Clean fluids, water, and gases. | Oil, petrochemical, and corrosive fluids. |

Proper installation and consistent care go a long way toward maintaining stable valve performance.

- Valve Orientation: Always align the valve according to the flow direction to prevent backflow problems and uneven seat wear.

- Pressure Drop Control: Monitor system pressure and flow rate regularly to avoid turbulence and erosion.

- Valve Inspection: Inspect periodically for stem leakage, corrosion signs, and seat wear.

- Lubrication: Keep trunnion bearings and stems well-lubricated for smooth operation and reduced friction.

- Cleaning and Flushing: After corrosive service, clean the internals to prevent buildup or contamination.

- Seat Replacement: In frequent-cycle systems, check and replace soft seats periodically to maintain consistent sealing.

Following these practices helps keep valves performing dependably and reduces long-term operating costs.

Which Valve Is Ideal and When

- Choose a floating ball valve for light-duty or moderate-pressure applications that handle clean media or water-based fluids. It’s an economical choice that offers steady shut-off performance.

- Opt for a trunnion ball valve in high-pressure, high-temperature, or corrosive environments where strength, endurance, and smooth actuation matter most.

Your choice should depend on pressure class, media type, and system size. Each valve type delivers reliable flow control when matched correctly to its application.

Both Floating and Trunnion Ball Valves play a vital role in maintaining consistent, one-direction flow control in industrial systems. Floating valves provide ease of maintenance and cost savings, while trunnion-mounted designs offer stable operation and longer service life in more demanding situations.

Whether your process involves oil, gas, water, or chemical service, our engineered valves promote smooth flow and protect your system from costly disruptions.

Share your process details-medium, temperature, and pressure-and our specialists will help you select the most suitable Floating or Trunnion Ball Valve for your operation.

Recent Posts

- Pressure Seal Gate Valves: Design Principle and High-Pressure Service

- Valves Used in Chemical Processing Plants

- Single Offset vs Double Offset vs Triple Offset Butterfly Valves – What’s the Difference?

- Globe Valve vs Ball Valve for Flow Control Applications: A Complete Comparison

- Forged vs Cast Valves: Differences, Strength & Applications for Corrosive Environments