Our Shop

Contact us for all your questions and requirements

Steam Trap Manufacturer in Europe – Valvesonly Europe (Germany)

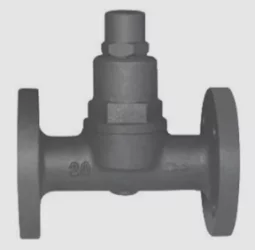

Valvesonly Europe manufactures steam traps in Germany engineered for efficient condensate discharge and energy savings in steam distribution systems. Our steam traps are designed to discharge condensate without steam loss, ensuring system efficiency, longer equipment life, and reduced operating costs. Built to EN, ISO, and ASME standards, our product range covers all major steam trap technologies, making them suitable for industrial, marine, power, and district heating applications.

Function & Working

Steam traps automatically separate and discharge condensate, air, and non-condensable gases from steam systems while retaining live steam. Depending on design, they operate using:

-

Density difference (float type) – discharges condensate continuously at steam temperature.

-

Temperature difference (thermostatic type) – opens when condensate cools below steam temperature.

-

Velocity dynamics (thermodynamic type) – simple disc design using Bernoulli’s principle for discharge.

By selecting the appropriate type, system efficiency is optimized while minimizing energy losses.

Advantages

-

Prevents water hammer and corrosion by removing condensate quickly

-

Zero steam loss designs improve energy efficiency

-

Long cycle life with hardened internals and corrosion-resistant housings

-

Suitable for saturated, superheated, and high-pressure steam systems

-

Compact construction for easy installation and maintenance

-

Tested and manufactured in Germany with PED/CE compliance

Types Offered

-

Float & Thermostatic (F&T) Steam Trap – continuous discharge for process heating and large condensate loads

-

Inverted Bucket Steam Trap – rugged design for fluctuating loads and dirt-laden service

-

Thermostatic Steam Trap – bimetallic or balanced pressure element for air-venting and variable load conditions

-

Thermodynamic Steam Trap – compact, stainless steel design for high-pressure steam lines and tracing

-

Clean Steam Trap – hygienic design for food, beverage, and pharmaceutical steam systems

Materials

| Category | Material | Standards / Grades | Typical Use |

|---|---|---|---|

| Cast Iron | EN-GJL-250 / ASTM A126 | Low-pressure steam systems | |

| Ductile Iron | EN-GJS-400-15 / ASTM A536 | Heating, HVAC, steam utilities | |

| Carbon Steel | WCB / ASTM A216 | Process steam, power plants | |

| Stainless Steel | CF8, CF8M, CF3, CF3M / ASTM A351 | Corrosive condensate, clean steam | |

| High Alloys | Monel, Inconel, Hastelloy, Alloy 20 | Aggressive chemical and refinery steam | |

| Internals | Hardened SS, Stellite, Tungsten Carbide | Long wear life, erosion resistance |

Technical Specifications

-

Types: Float & Thermostatic, Inverted Bucket, Thermostatic, Thermodynamic, Clean Steam

-

Size Range: DN15 – DN100

-

Pressure Ratings: PN10 – PN420 / Class 150 – 2500

-

Temperature Range: –40 °C to +560 °C (depending on design)

-

End Connections: Screwed (NPT/BSP), Socket Weld (SW), Butt Weld (BW), Flanged (EN 1092 / ASME)

-

Testing Standards: EN 12266-1 leakage test, API 598, ISO 6554

-

Certifications: PED/CE, EN 13445, ATEX (for hazardous areas)

Showing all 5 results