We deliver to you every day from 7:00 to 23:00

Pressure Seal Gate Valves: Design Principle and High-Pressure Service

Pressure seal gate valves are used when operating pressure and temperature exceed the practical limits of conventional bolted bonnet designs. For engineers and buyers evaluating a Pressure Seal Gate Valve Manufacturer in Europe, these valves are typically specified for high-pressure steam lines, boiler feed water circuits, and critical hydrocarbon services where bonnet leakage becomes a

Valves Used in Chemical Processing Plants

Chemical processing plants rely on controlled fluid handling to maintain safety, efficiency, and product quality. Valves Used in Chemical Processing Plants play a critical role in regulating flow, isolating systems, and protecting equipment across diverse process units. These facilities handle corrosive chemicals, high pressures, wide temperature ranges, and complex reactions, making valve selection a technical

Single Offset vs Double Offset vs Triple Offset Butterfly Valves – What’s the Difference?

In corrosive environments involving seawater, brine, acids, caustics, hydrocarbons, or chemical slurries, valve materials and seating mechanisms must deliver long-term durability. Offset butterfly valves are designed to reduce contact between the disc and seat, minimizing wear and extending operating life. Materials used for corrosive applications include: Understanding the offset configuration helps determine which material and

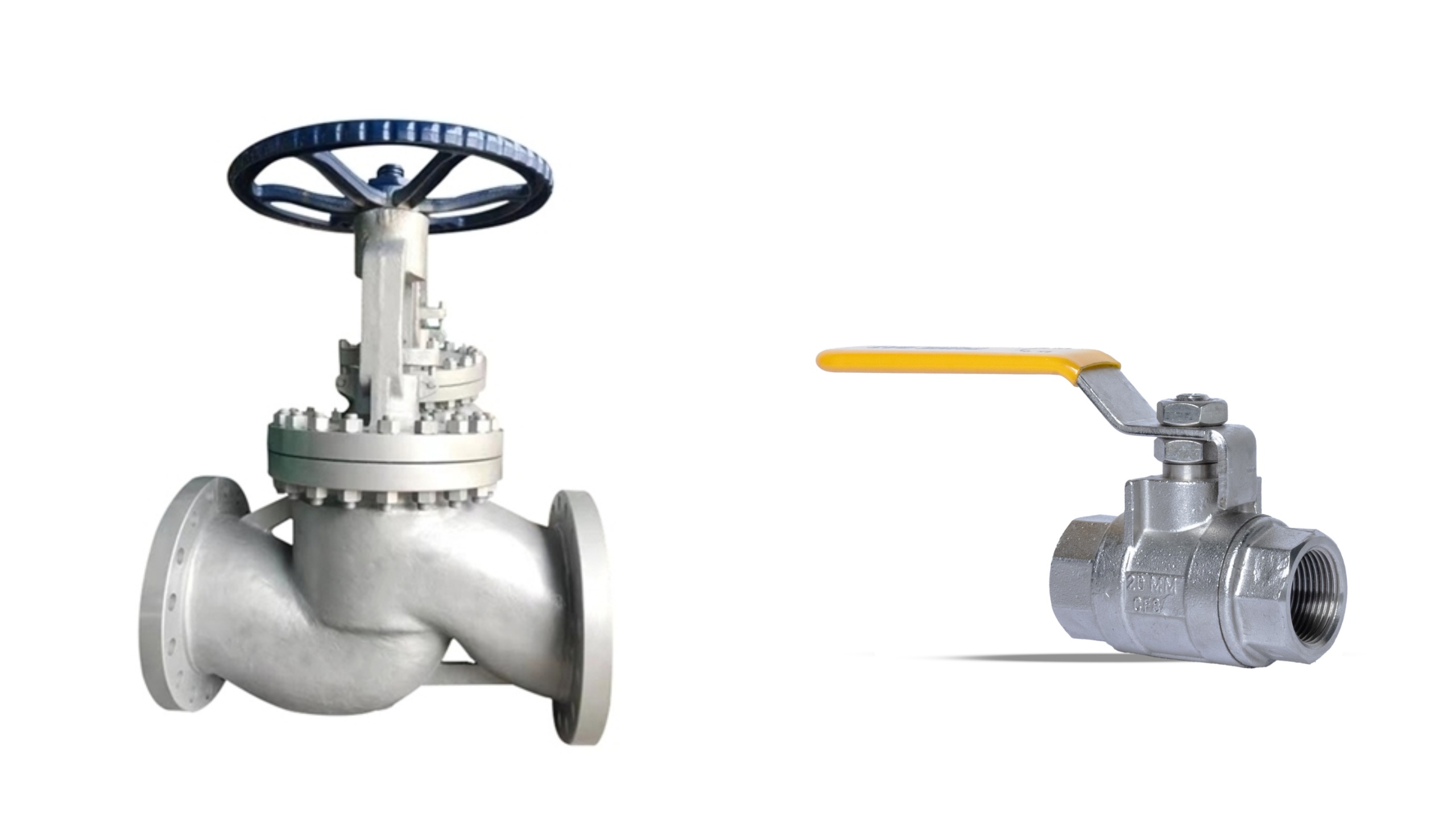

Globe Valve vs Ball Valve for Flow Control Applications: A Complete Comparison

Backflow problems, pressure instability, and irregular flow control often lead to system inefficiencies and costly downtime. Industries handling steam, chemicals, or corrosive fluids frequently evaluate valve types based on performance, safety, and flow behavior. In this blog, we will be discussing Globe Valve vs Ball Valve, a detailed comparison often searched by engineers working with

Forged vs Cast Valves: Differences, Strength & Applications for Corrosive Environments

In this blog, we will be discussing Forged vs Cast Valves-two valve manufacturing methods that are often evaluated side-by-side when selecting equipment for demanding industrial processes. But before we get into the materials and mechanical performance, it’s important to highlight the real concerns engineers deal with daily: backflow issues, pressure spikes, valve orientation limitations, and

Rising Stem vs Non-Rising Stem Gate Valve Material Benefits for Corrosive Applications

In this blog, we will be discussing Rising Stem vs Non-Rising Stem Gate Valve, a comparison that matters deeply for corrosive service industries. But before going into technical specifications, let’s slow down and address one of the biggest challenges plant operators face today: backflow problems and sudden pressure fluctuations that can compromise safety. Many failures

Valve Certification Standards in Europe: ISO, API, and PED Explained

A single valve failure can compromise plant safety, interrupt operations, and cause costly downtime. Backflow, leakage, contamination, uncontrolled pressure surges, or unplanned shutdowns can escalate into severe operational risks. This is why selecting valves that comply with the correct European certification standards is not simply a regulatory formality, it is a fundamental requirement for mechanical

Check Valve vs Non-Return Valve – Are They the Same Thing?

In this blog, we’re exploring one of the most common confusions in fluid control systems – Check Valve vs Non-Return Valve. If you’ve ever dealt with backflow problems, pressure fluctuations, or unplanned shutdowns in a pipeline, you already know how critical these valves are for system safety and efficiency. Both valves perform the same essential

Understanding Butterfly Valve Types – Wafer, Lug, Double and Triple Offset

In this blog, we’ll take a closer look at how Butterfly Valves function, their different configurations like wafer, lug, double offset, and triple offset, and why these valves are a preferred choice for modern industrial operations. As a Butterfly Valves manufacturer in Europe, Valves Only Europe specializes in engineering precision-built valves that maintain consistent flow

Pressure Relief Valves vs Safety Valves – When and How to Use Them

In this Blog, we’ll talk about Pressure Relief Valves vs Safety Valves, two essential valve types that protect pressurized systems from dangerous overpressure. We will talk about why these valves are often compared, how they differ in function, and which one suits your specific system needs. Whether you’ve dealt with backflow issues, pressure drops, or

Recent Posts

- Pressure Seal Gate Valves: Design Principle and High-Pressure Service

- Valves Used in Chemical Processing Plants

- Single Offset vs Double Offset vs Triple Offset Butterfly Valves – What’s the Difference?

- Globe Valve vs Ball Valve for Flow Control Applications: A Complete Comparison

- Forged vs Cast Valves: Differences, Strength & Applications for Corrosive Environments