Our Shop

Contact us for all your questions and requirements

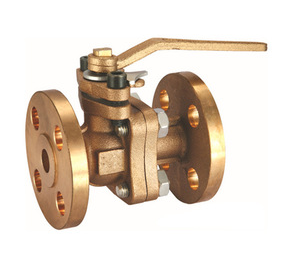

API Gate Valve Manufacturer in Italy – Valvesonly Europe

Valvesonly Europe is an API Gate Valve Manufacturer in Italy, specializing in high-performance isolation valves designed for oil and gas, petrochemical, refinery, power, and industrial service applications. Our valves are manufactured in Italy in compliance with API 600, API 602, API 603, and API 6D standards, and certified under PED 2014/68/EU for use in the European market. Each valve is designed for precise operation, reliable sealing, and long service life under demanding process conditions.

Function & Working

An API gate valve isolates flow through the linear movement of a wedge or slab that travels perpendicular to the flow path. When fully open, the unobstructed bore provides straight-through flow with negligible pressure drop. When closed, the wedge or slab seals tightly against the body seats to achieve complete shutoff. Different designs such as flexible wedge, solid wedge, slab, and parallel slide are available to suit various pressure and temperature conditions, including thermal expansion and high cycling service.

Advantages

Complies with API 600, API 602, API 603, API 6D, and PED 2014/68/EU

Low operating torque with full-bore flow passage

Bolted or pressure seal bonnet construction for different pressure ranges

Hard-faced seat rings for wear and erosion resistance

Rising or non-rising stem options

Optional bypass and drain arrangement

Renewable trim for easy maintenance and long service life

Types of API Gate Valves Manufactured

Bolted Bonnet Gate Valve

Pressure Seal Bonnet Gate Valve

Flexible Wedge Gate Valve

Solid Wedge Gate Valve

Parallel Slide Gate Valve

Slab Gate Valve (API 6D)

Bellow Seal Gate Valve

Through Conduit Gate Valve

Industries Served

Oil and Gas Production and Refining

Petrochemical and Chemical Processing

Power Generation and Steam Systems

Offshore and Onshore Pipelines

Water Injection and Utility Systems

Industrial Process and Plant Piping

Materials (Body, Bonnet, Trim, and Seats)

| Category | Material | Standard / Grade | Typical Application |

|---|---|---|---|

| Carbon Steel | ASTM A216 WCB / WCC | API / ASME / EN | Hydrocarbon and general process service |

| Low Temperature Carbon Steel | ASTM A352 LCB / LCC | ASME / EN | Cryogenic and sub-zero applications |

| Stainless Steel | CF8, CF8M, CF3, CF3M (ASTM A351) | — | Corrosive and chemical media |

| Duplex and Super Duplex | ASTM A890 CD4MCu, S32750, S32760 | — | Seawater, desalination, and chloride-rich fluids |

| Alloy Steel | ASTM A217 WC6, WC9, C5, C12 | — | High-temperature and steam service |

| Aluminium Bronze | C95400, C95800 (ASTM B148) | — | Marine and seawater systems |

| Exotic Alloys | Monel, Inconel, Hastelloy, Titanium, Alloy 20 | — | Aggressive and acidic environments |

| Trim (Seat, Stem, Guide) | SS410, SS420, SS316, Stellite 6, Colmonoy | ASTM A276 / AWS | Erosion and wear resistance |

Technical Specifications

Design Standards: API 600, API 602, API 603, API 6D, ASME B16.34, EN 1984, PED 2014/68/EU

Testing Standards: API 598, EN 12266-1

Size Range: DN50 – DN1200 (2″ – 48″)

Pressure Ratings: PN10 – PN420 / ANSI Class 150 – 2500

Temperature Range: –46 °C to +600 °C (depending on material)

End Connections: Flanged (EN 1092 / ASME B16.5), Butt Weld (BW), Socket Weld (SW)

Operation: Manual (Handwheel / Gear), Electric, or Pneumatic Actuator

Seat Options: Metal-to-Metal or Soft-Seated depending on application

Special Features

Fire-safe and anti-static construction

Stem backseat arrangement for packing replacement under pressure

Pressure equalizing bypass available on request

Replaceable seat rings and renewable trim

Full-bore or reduced-bore design as per API 6D

Hydrostatic and seat leakage testing as per API 598

Why Choose Valvesonly Europe

Manufactured in Italy under API and PED-certified systems

Comprehensive range covering API 600 to API 6D designs

Flexible material options including WCB, Stainless Steel, Duplex, and Alloys

Custom-engineered solutions for high-pressure and high-temperature service

Reliable delivery with full EN 10204 3.1 certification and test documentation

Showing the single result