Description

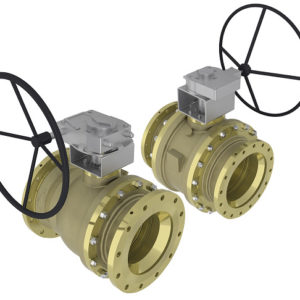

Titanium Swing Check Valve

Manufacturing Standards:API, ANSI, BS, DIN, JIS.

Valve Pressure:150LB to 2500LB (PN1.6-42MPa).

Check Valve Size range:1/2 to 32 Inch (DN15 to DN800).

Operating temperature:from -196 degrees Celsius to 593 degrees Celsius.

Connection:Flanged, Butt-welded.

Face to Face Dimensions:ANSI B16.10.

Flange end Dimension:ANSI B16.5

Butt Welded Dimensions:ANSI B16.25

Design and Manufacture:BS1868

Pressure Test:API598

| Pressure (Mpa) | PN1.6Mpa | ||||||||||

| Size mm | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 |

| L | 230 | 290 | 310 | 350 | 400 | 480 | 550 | 650 | 750 | 850 | 950 |

| H | 305 | 354 | 402 | 437 | 496 | 541 | 699 | 815 | 914 | 1189 | 1350 |

| Wt(kg) | 21 | 28 | 38 | 58 | 92 | 130 | 210 | 295 | 365 | 410 | 460 |

| Pressure (Mpa) | PN2.5Mpa | ||||||||||

| Size mm | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 |

| L | 230 | 290 | 310 | 350 | 400 | 480 | 550 | 650 | 750 | 850 | 950 |

| H | 305 | 363 | 415 | 453 | 505 | 556 | 744 | 864 | 948 | 1269 | 1450 |

| Wt(kg) | 21 | 29 | 38 | 61 | 96 | 132 | 213 | 297 | 375 | 415 | 460 |

API Trim NO. Table

|

No of internal parts |

Seat ring or body |

Gate, disc, ball or body |

Stem |

No of internal parts |

Seat ring or body |

Gate, disc, ball or body |

Stem |

|

|

01 |

13Cr |

13Cr |

13Cr |

31 |

STELLITE |

321SS |

321SS |

|

|

02 |

304SS |

304SS |

304SS |

32 |

STELLITE |

STELLITE |

321SS |

|

|

03 |

310SS |

310SS |

310SS |

33 |

347SS |

347SS |

347SS |

|

|

04 |

HARD 13Cr |

HARD 13Cr |

13Cr |

34 |

STELLITE |

347SS |

347SS |

|

|

05 |

STELLITE |

STELLITE |

13Cr |

35 |

NICKEL ALLOY |

13Cr |

13Cr |

|

|

06 |

Cu-Ni |

13Cr |

13Cr |

36 |

A105/PTFE |

A105+ENP |

A105+ENP |

|

|

07 |

13Cr |

HARD 13Cr |

13Cr |

37 |

A105/PTFE |

WCB+ENP |

A105+ENP |

|

|

08 |

STELLITE |

13Cr |

13Cr |

38 |

13Cr/PTFE |

13Cr |

13Cr |

|

|

09 |

Cu-Ni |

Cu-Ni |

Cu-Ni |

39 |

304SS/PTFE |

304SS |

304SS |

|

|

10 |

316SS |

316SS |

316SS |

40 |

316SS/PTFE |

316SS |

316SS |

|

|

11 |

Cu-Ni |

STELLITE |

Cu-Ni |

41 |

A105/RPTFE |

A105+ENP |

A105+ENP |

|

|

12 |

STELLITE |

316SS |

316SS |

42 |

A105/RPTFE |

WCB+ENP |

A105+ENP |

|

|

13 |

ALLOY 20 |

ALLOY 20 |

ALLOY 20 |

43 |

13Cr/RPTFE |

13Cr |

13Cr |

|

|

14 |

STELLITE |

ALLOY 20 |

ALLOY 20 |

44 |

304SS/RPTFE |

304SS |

304SS |

|

|

15 |

STELLITE |

STELLITE |

304SS |

45 |

316SS/RPTFE |

316SS |

316SS |

|

|

16 |

STELLITE |

STELLITE |

316SS |

46 |

A105/NYLON |

A105+ENP |

A105+ENP |

|

|

17 |

STELLITE |

STELLITE |

347SS |

47 |

A105/NYLON |

WCB+ENP |

A105+ENP |

|

|

18 |

STELLITE |

STELLITE |

ALLOY 20 |

48 |

A105/NYLON |

304SS |

304SS |

|

|

19 |

MONEL |

MONEL |

MONEL |

49 |

A105/NYLON |

316SS |

316SS |

|

|

20 |

BRONZE |

BRONZE |

13Cr |

50 |

13Cr/NYLON |

13Cr |

13Cr |

|

|

21 |

HASTELLOY B |

HASTELLOY B |

HASTELLOY B |

51 |

304SS/NYLON |

304SS |

304SS |

|

|

22 |

HASTELLOY C |

HASTELLOY C |

HASTELLOY C |

52 |

316SS/NYLON |

316SS |

316SS |

|

|

23 |

STELLITE |

304SS |

304SS |

53 |

A105/PEEK |

A105+ENP |

A105+ENP |

|

|

24 |

304LSS |

304LSS |

304LSS |

54 |

A105/PEEK |

WCB+ENP |

A105+ENP |

|

|

25 |

STELLITE |

304LSS |

304LSS |

55 |

13Cr/PEEK |

13Cr |

13Cr |

|

|

26 |

STELLITE |

STELLITE |

304LSS |

56 |

304SS/PEEK |

304SS |

304SS |

|

|

27 |

316LSS |

316LSS |

316LSS |

57 |

316SS/PEEK |

316SS |

316SS |

|

|

28 |

STELLITE |

316LSS |

316LSS |

|

|

|

|

|

|

29 |

STELLITE |

STELLITE |

316LSS |

|

|

|

||

|

30 |

321SS |

321SS |

321SS |

|

|

|

|

|

Reviews

There are no reviews yet.